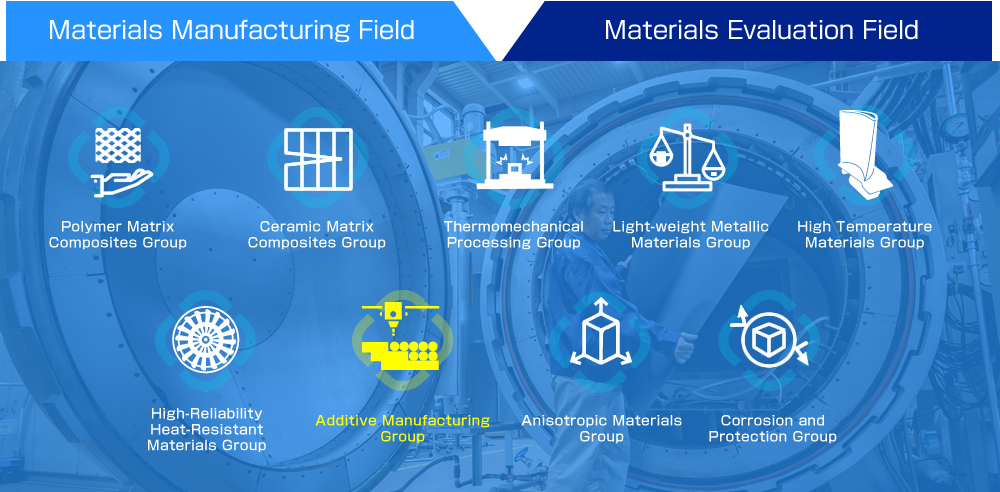

↑Click on the icon to go to other groups

↑Click on the icon to go to other groups

Additive Manufacturing Group

Permanent Employee

Makoto Watanabe

Deputy Director, Research Center for Structural Materials

Group Leader

Keyword : additive manufacturing, thermal spray coatings, metallic materials, heat-resistant materials, materials integration, DX, numerical simulation![]()

Dongfeng He

Principal Researcher

Keyword : magnetic sensors, nondestructive testing, thermography, eddy current, electromagnetic, rebar corrosion, laminate material defects

Tomonori Kitashima

Principal Researcher![]()

Keyword : titanium alloy, nickel-based superalloy, additive manufacturing, high-temperature deformation, microstructure control, precipitation, phase transformation, texture, single crystal![]()

Christopher Mercer

Principal Researcher

Keyword : low thermal expansion, auxetics, lattices, additive manufacturing, geometry optimization

Masahiro Kusano

Senior Researcher

Keyword : metal additive manufacturing, finite element thermal analysis, process monitoring, microstructure control![]()

Fabien Briffod

Researcher

Keyword : Crystal Plasticity, Finite Element Method, Continuum Mechanics, Fatigue and Fracture, Digital Image Correlation

Fixed Term Employee

NIMS Special Researcher

Keyword : Multi-phase field method coupled with CALPHAD,

Lattice Boltzmann method, Computational fluid dynamics,

Multi-physics & scale simulation for additive manufacturing

NIMS Special Researcher

NIMS Special ResearcherKeyword : Additive manufacturing, High-temperature superalloy, Phase and microstructure control

Trainee

- Taisei Nakayama

NIMS Junior Researcher - Medha Shrey

NIMS Internship - Subhakar Mangam

International Cooperative Graduate Program - Li He

Trainee - Marie Maximilien Louis Galiegue

Trainee

Publications

2025

![]() Meng L., Kitashima T., Lin P., Wang Z., Jiang Z., Huang Q., Zhao J.

Meng L., Kitashima T., Lin P., Wang Z., Jiang Z., Huang Q., Zhao J.

Achieving polymer-like ultrahigh elasticity in Ti−6Al−4V alloy via a new cryo-deformation induced α′-to-α″ martensite phase transformation

Acta Materialia.293(2025)121109

![]() Daram P., Kusano M., Watanabe M.

Daram P., Kusano M., Watanabe M.

Investigation of the Process Optimization for L-PBF Hastelloy X Alloy on Microstructure and Mechanical Properties

Materials.18[8](2025)1890

![]() Bhandari L., Gaur V., Briffod F., Shiraiwa T., Enoki M.

Bhandari L., Gaur V., Briffod F., Shiraiwa T., Enoki M.

High-temperature fatigue and creep damage mechanism in additively manufactured Ti-6Al-4V alloy

Engineering Failure Analysis.174(2025)109534

Katagiri J., Nomoto S., Kusano M., Watanabe M.

Influence of high Reynolds number flow inside molten pool on keyhole instability-induced pore formation process in laser powder bed fusion

Materials Today Communications.44(2025)111756

Nomoto S., Kusano M., Kitashima T., Watanabe M.

Numerical simulation method for the laser powder bed fusion process by lattice Boltzmann and multi-phase field methods

Computational Materials Science.250(2025)113688

Meng L., Kitashima T., Lin P., Zheng L., Jiang Z., Zhao J.

In situ EBSD investigation of microtexture evolution and slip activation of α macrozones during tensile deformation in Ti-6Al-4V alloy

Materials Science and Engineering: A.924(2025)147739

Honda H., Watanabe M.

Measurement of Laser Absorptivity of Inconel Powders with Additive Manufacturing Machine

Materials Transactions.66[1](2025)107-112

Briffod F., Yasuda K., Zhu J., Shiraiwa T., Jhon M., Gunawan F., Sahay R., Raghavan N., Budiman A.S., Enoki M.

Fatigue and fracture of accumulative roll-bonded Cu/Nb materials: Effects of layer thickness and loading direction

International Journal of Fatigue.193(2025)108772

2024

Mercer C., Hasegawa A., Hosoda N.

Surface-activated bonding between a 3D-printed Ti-6Al-4V structure and bulk aluminum

Journal of Materials Science: Materials in Engineering.19[1](2024)47

Kuroda T., Masuyama H., Toda Y., Matsunaga T., Ito T., Watanabe M., Ozasa R., Ishimoto T., Nakano T., Shimojo M., Yamabe–Mitarai Y.

Microstructure Evolution and High–Temperature Mechanical Properties of Ti–6Al–4Nb–4Zr Fabricated by Selective Laser MeltingNippon Kinzoku Gakkaishi/Journal of the Japan Institute of Metals.88[12](2024)348-356

Bulgarevich D.S., Watanabe M.

Stress–strain curve predictions by crystal plasticity simulations and machine learning

Scientific Reports.14[1](2024)29492

Hagiwara M., Kitashima T.

High Cycle Fatigue and Very High Cycle Fatigue of Orthorhombic (O + α2)–Type Ti–27.5Nb–13Al Alloy with and without B and Fatigue Striation Analysis in Comparison with (α + β)–Type Titanium Alloys

Nippon Kinzoku Gakkaishi/Journal of the Japan Institute of Metals.88[12](2024)357-366

Katagiri J., Nomoto S., Kusano M., Watanabe M.

Effect of mushy zone constant in Voller-Prakash model on keyholing behaviour in laser powder bed fusion simulation

Results in Engineering.24(2024)103567

Verona I.C.M., Bardolaza H.R., Juguilon V.P.P., Bulgarevich D.S., Watanabe M., Tani M., Estacio E.S.

Investigation of Spin-Current Lifetime in Fe/Pt Spintronic Terahertz Emitter using Double Optical Pump Technique

International Conference on Infrared, Millimeter, and Terahertz Waves, IRMMW-THz.(2024)

Kusano M., Watanabe M.

Controlling heat accumulation through changing time per layer in laser powder bed fusion of nickel-based superalloy

Journal of Manufacturing Processes.131(2024)187-198

Hatakeyama T., Sawada K., Kusano M., Watanabe M.

Significant creep-strength improvement in modified 9Cr-1Mo steel via microstructural control through laser powder bed fusion

Additive Manufacturing.93(2024)104445

Morimoto T., Katoh H., Ishida Y., Hara E., Kusano M., Naito K., Watanabe M., Takagi K., Arai K., Hasegawa K.

Modified double cantilever beam test method for mode-I energy release rate of elastic adhesive layers

Engineering Fracture Mechanics.307(2024)110320

Daram P., Morisada Y., Ogura T., Kusano M., Yu J., Fukuda M., Fujii H., Kuroda S., Watanabe M.

Development of Tungsten Repair Technology by Atmospheric Plasma Spraying of Tungsten and Friction Stir Processing

Journal of Thermal Spray Technology.(2024)

Daram P., Singh A., Hiroto T., Kitashima T., Watanabe M.

Compositionally graded titanium to aluminum processed by laser powder bed fusion process: Microstructure evolution and mechanical properties

Materials Science and Engineering: A.903(2024)146638

Kitashima T., Hiroto T., Jodi D.E., Watanabe M.

Fabricating a single-crystal-like β grain structure of a near-β Ti alloy with unique variant selection by laser powder bed fusion

Materials and Design.243(2024)113039

Katagiri J., Nomoto S., Kusano M., Watanabe M.

Particle Size Effect on Powder Packing Properties and Molten Pool Dimensions in Laser Powder Bed Fusion Simulation

Journal of Manufacturing and Materials Processing.8[2](2024)71

Kitashima T., Hiroto T., Watanabe M.

Numerical analysis of Al2O3 and TiO2 growth and oxygen dissolution in a metal substrate during the isothermal oxidation of an α-Ti alloy at 973 K

Journal of Materials Research and Technology.30(2024)4137-4146

Okugawa M., Saito K., Yoshima H., Sawaizumi K., Nomoto S., Watanabe M., Nakano T., Koizumi Y.

Solute segregation in a rapidly solidified Hastelloy-X Ni-based superalloy during laser powder bed fusion investigated by phase-field and computational thermal-fluid dynamics simulations

Additive Manufacturing.84(2024)104079

Mercer C., Hosoda N.

Analysis of Structure and Function of Ladybird Leg and Subsequent Design and Fabrication of a Simplified Leg Structure for Robotic Applications

Biomimetics.9[3](2024)184

Honda H., Watanabe M.

Quantifying Laser Absorptivity of Ti–6Al–4V Powder through Additive Manufacturing Systems

Materials Transactions.65[2](2024)194-198

Kusano M., Takata Y., Yumoto A., Watanabe M.

Effects of time per layer and part geometry on thermal history and microcracking in the fabrication of nickel superalloy samples by laser powder bed fusion

Additive Manufacturing.80(2024)103987

Kusano M., Watanabe M.

Heat Source Model Development for Thermal Analysis of Laser Powder Bed Fusion Using Bayesian Optimization and Machine Learning

Integrating Materials and Manufacturing Innovation.(2024)

2023年

Zhu J., Briffod F., Shiraiwa T., Enoki M., Emura S.

Kink band formation mechanism in α/β Ti-9Cr two-phase alloy

Journal of Alloys and Compounds.939(2023)168736

Wang Q., Ma N., Huang W., Shi J., Luo X.-T., Tomitaka S., Morooka S., Watanabe M.

Key role of temperature on delamination in solid-state additive manufacturing via supersonic impact

Materials Research Letters.11[9](2023)742-748

Wang Q., Ma N., Chen J., Tomitaka S., Watanabe M.

Microstructure characteristics of warm spray additively manufactured Inconel 718 superalloys and correlation with mechanical performance

Materials Letters.341(2023)134230

Talara M., Bulgarevich D.S., Kobayashi K., Kitahara H., Furuya T., Escano M.C., Watanabe M., Tani M.

Impact of Antenna Metal's Thicknesses and Structures on Terahertz (THz) Wave Generation Performance of Spintronic Emitters

International Conference on Infrared, Millimeter, and Terahertz Waves, IRMMW-THz.(2023)

Osada T., Koyama T., Bulgarevich D.S., Minamoto S., Osawa M., Watanabe M., Kawagishi K., Demura M.

Virtual heat treatment for γ-γ′ two-phase Ni-Al alloy on the materials Integration system, MInt

Materials and Design.226(2023)111631

Meng L., Kitashima T., Zhao Z., Wei Q., Lin P.

Effect of parent β-texture on α-texture evolution during dynamic precipitation in a continuous forging process of Ti-6Al-4V alloy

Journal of Alloys and Compounds.947(2023)169425

Kuroda T., Masuyama H., Toda Y., Matsunaga T., Ito T., Watanabe M., Ozasa R., Ishimoto T., Nakano T., Shimojo M., Yamabe-Mitarai Y.

Microstructure Evolution and High-Temperature Mechanical Properties of Ti6Al4Nb4Zr Fabricated by Selective Laser Melting

Materials Transactions.64[1](2023)95-103

Katagiri J., Kusano M., Minamoto S., Kitano H., Daimaru K., Tsujii M., Watanabe M.

Melt Pool Shape Evaluation by Single-Track Experiments and Finite-Element Thermal Analysis: Balling and Lack of Fusion Criteria for Generating Process Window of Inconel738LC

Materials.16[4](2023)1729

Jodi D.E., Kitashima T., Singh A., Watanabe M.

High-temperature microstructural stability of pure Ni fabricated by laser powder bed fusion using Gaussian and flat-top beam profiles

Materials Characterization.200(2023)112897

Hatakeyama T., Sawada K., Suzuki M., Watanabe M.

Microstructure development of modified 9Cr-1Mo steel during laser powder bed fusion and heat treatment

Additive Manufacturing.61(2023)103350

Hagiwara M., Kitashima T.

High Cycle Fatigue and Very High Cycle Fatigue of Orthorhombic (O + α 2 )-Type Ti–27.5Nb–13Al Alloy with and without B and Fatigue Striation Analysis in Comparison with (α + β)-Type Titanium Alloys

Materials Transactions.64[1](2023)121-130

Daram P., Hiroto T., Watanabe M.

Microstructure and phase evolution of functionally graded multi-materials of Ni–Ti alloy fabricated by laser powder bed fusion process

Journal of Materials Research and Technology.23(2023)5559-5572

Bulgarevich D.S., Nomoto S., Watanabe M., Demura M.

Crystal plasticity simulations with representative volume element of as-build laser powder bed fusion materials

Scientific Reports.13[1](2023)20372

Zhu J., Briffod F., Shiraiwa T., Enoki M., Emura S.

High-Resolution Digital Image Correlation Analysis of Layered α/β Two-Phase Ti–12Mo Alloy under Compressive Condition

Materials Transactions.64[12](2023)2677-2686

Kitahara H., Ishii K., Talara M., Furuya T., Escano M.C., Tani M., Bulgarevich D.S., He D., Watanabe M.

Improvement in the Detection Efficiency of Terahertz (THz) Time-domain Spectroscopy (TDS) by applying an Alternating Magnetic Field Bias in Spintronic Emitter

International Conference on Infrared, Millimeter, and Terahertz Waves, IRMMW-THz.(2023)

About us

Additive Manufacturing Group studies on additive manufacturing (3D printer), which has been attracting a lot of interest as a next-generation process technology, and thermal spray processing, which is important for a protective coating of a structural component in harsh environments. The group focuses on heat-resistant materials (Ni-based alloys, Ti alloys, oxide ceramics, etc.) used in jet engines, gas turbines, and other high-temperature energy equipment.

Group research overview

In this group, mainly four research topics have been investigated, (i) 3D additive manufacturing process that directly creates complex three-dimensional structures from raw material powder, (ii) Coating technology to protect structural components from harsh environments, and (iii) Nondestructive evaluation techniques for ensuring reliability of materials.

Research theme

Selective laser Melting

Sukeharu Nomoto, Masahito Segawa, Makoto Watanabe. Non- and Quasi-Equilibrium Multi-Phase Field Methods Coupled with CALPHAD Database for Rapid-Solidification Microstructural Evolution in Laser Powder Bed Additive Manufacturing Condition. Metals. (2021) 626-1-626-21 10.3390/met11040626

KITANO, Houichi, TSUJII, Masakazu, KUSANO, Masahiro, Atsushi Yumoto, WATANABE, Makoto. Effect of plastic strain on the solidification cracking of Hastelloy-X in the selective laser melting process. Additive Manufacturing. (2021) 101742-1-101742-9

Kaita Ito, Masahiro Kusano, Masahiko Demura, Makoto Watanabe. Detection and location of microdefects during selective laser melting by wireless acoustic emission measurement. Additive Manufacturing. 40 (2021) 101915 10.1016/j.addma.2021.101915

Image Segmentation and Analysis for Microstructure and Property Evaluations on Ti–6Al–4V Fabricated by Selective Laser Melting

Spray Coating

Effects of Gun Scanning Pattern on the Structure, Mechanical Properties and Corrosion Resistance of Plasma-Sprayed YSZ Coatings

Effects of amorphous phase on hot corrosion behavior of plasma-sprayed LaMgAl11O19 coating

Non-destructive Evaluation

Evaluation of 3D-Printed titanium alloy using eddy current testing with high-sensitivity magnetic sensor

Terahertz Magneto-Optic Sensor/Imager

Mid-infrared pulsed laser ultrasonic testing for carbon fiber reinforced plastics

Forging

Effect of α precipitation on β texture evolution during β-processed forging in a near-β titanium alloy