↑Click on the icon to go to other groups

↑Click on the icon to go to other groups

Welding and Joining Technology Group

Welding and joining technologies are essential for development of social infrastructure. However, a reliable data for predicting and evaluating the deterioration of weldments is insufficient so far. In this project, we aim to develop a new technology for predicting the performance of weldments based on observation of welding behaviors, defect formation mechanism during welding, and database for weldment properties using in situ observation, advanced evaluation technique, and data science.

Members

Tomoya Nagira

Group Leader, Welding and Joining Technology Group, Materials Evaluation Field, Research Center for Structural Materials

Keyword : welding, joining, in-situ observation, microstructure formation, structuring![]()

![]()

Houichi Kitano

Principal Researcher, Welding and Joining Technology Group, Materials Evaluation Field, Research Center for Structural Materials

Keyword : welding, steel, machine learning, welding digital transformation

Specialized Research Field

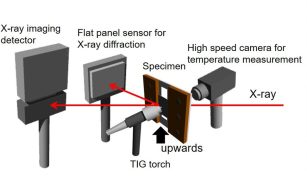

1. In situ observation of solidification behaviors during arc welding using synchrotron X-ray

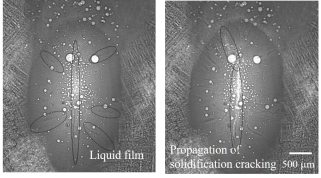

Synchrotron X-ray at SPring-8 makes it possible to directly observe the solidification behaviors of metallic alloys at a microstructural scale due to monochromatic light, high coherency and high brightness. This project focuses on the development of the technique for directly observing welding behaviors using synchrotron X-ray imaging and diffraction for various metallic alloys such as Al alloy, carbon steel and stainless steel. We also aim to elucidate the formation mechanism of solidification cracking in terms of microstructural evolution, strain/strain rate and brittle temperature range (BTR).

Schematic of experimental set-up for in situ observation during arc welding

X-ray radiographs of solidification cracking at weld crater

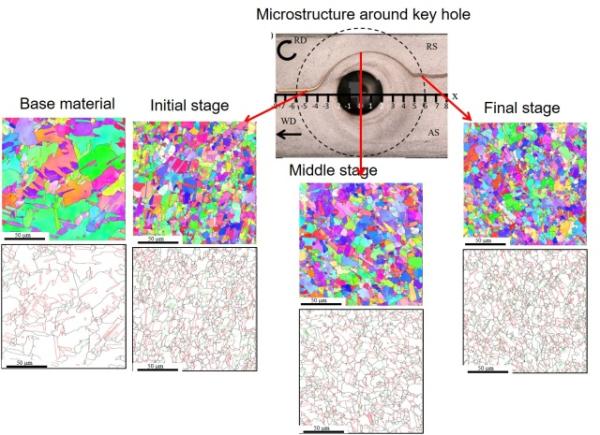

2. Development of solid-state joining (Friction stir welding) technique

Friction stir welding (FSW) is a promising joining technique due to the potential benefits such as avoidance of crack formation and high distortion. The microstructure is generally evolved through complex processes including plastic deformation, dynamic recrystallization and grain growth because of mechanical and thermal effects. In this project, we aim to elucidate the microstructural evolution mechanism during FSW for various metals with different stacking fault energies (SFE) such as Al, Cu, brass and Ag by examining the effects of SFE, recrystallization temperature and welding conditions on the microstructure.

Grain structure development during friction stir welding

3. Development of welding process and welding materials

We develop the welding process and welding materials. In recent years, Mn steel with enhanced low-cycle fatigue resistance has been developed at NIMS. In order to weld Mn steel, new welding materials and the welding process were developed. These welding materials and welding process allowed the production of the seismic damper of the welding structure. New welding process and welding consumable were applied to various buildings.

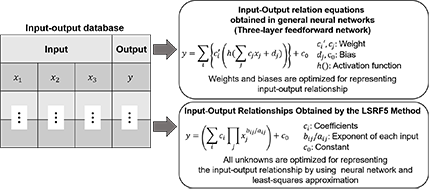

4. Application of Machine Learning for Understanding and Analysis of Welding Phenomena

Arc welding is a complex phenomenon in which four states (solid-liquid-gas-plasma) affect each other at multi-scales. Therefore, the relationship between the arc welding conditions and the characteristics of the arc weld (melting condition, joint strength, fatigue characteristics, etc.) is also complex and difficult to analyze. We are investigating the quantitative and systematic understanding of the relationship between arc welding conditions and weld characteristics, including the development of a unique machine learning technique to model the relationship in an easy-to-understand way like an experiment formula.

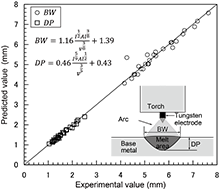

Input-output relation equations obtained by neural networks and the LSRF5 method (Developed method)

Penetration shape prediction of weld part by LSRF5 method

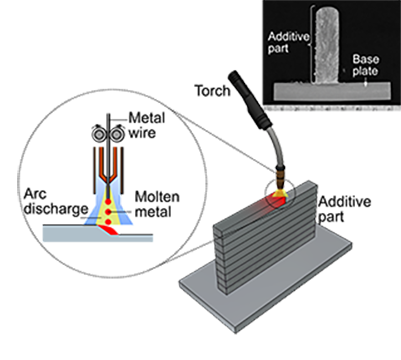

5. Advancement of Metal 3D Printing Technique based on Arc Welding

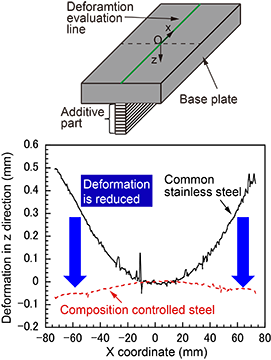

Wire and Arc Additive Manufacturing (WAAM) is a metal 3D printing technique that uses arc welding as a metal melting and solidification technique. We aim to use our knowledge of arc welding to advance WAAM. It was demonstrated that the amount of deformation of parts made by WAAM could be reduced by using the composition-controlled steel material. The material was developed to reduce the amount of deformation of arc weld joints. In addition, we are conducting research on the creation of composite steel materials with high strength and high ductility that combine high strength and high ductility steels in millimeter-scale.

Overview of WAAM technique

Overview of WAAM technique

Effect on deformation reduction of WAAM part by use of composition controlled steel