↑Click on the icon to go to other groups

↑Click on the icon to go to other groups

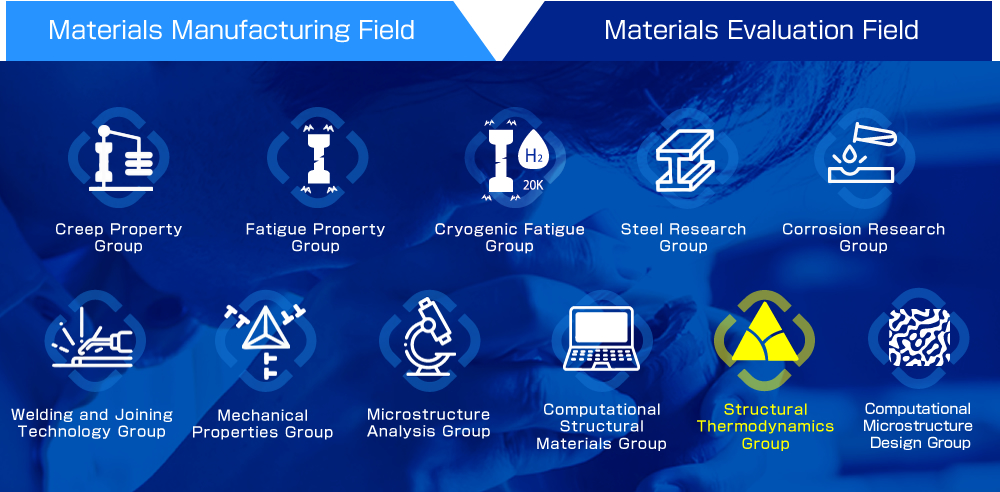

Structural Thermodynamics Group

In the development of various materials, precise control of microstructures is a key factor where thermodynamics and dynamics can play an important role. Using the CALPHAD (CALculation of PHAse Diagrams) and Phase-Field methods, our group aims to provide guiding principles for the development of new materials by analyzing the primary factors of various material properties through phase diagrams, thermodynamics, and dynamic simulations, which are the basis of the material and process design.

Members

Taichi Abe

Group Leader, Structural Thermodynamics Group, Materials Evaluation Field, Research Center for Structural Materials

Keyword : CALPHAD method, computational thermodynamics, phase equilibria, permanent magnet materials, heat-resistant alloys

Machiko Ode

Senior Researcher, Structural Thermodynamics Group, Materials Evaluation Field, Research Center for Structural Materials

Keyword : computer simulation, phase-field method, microstructure of materials

Specialized Research Field

1. Thermodynamic analysis by CALPAHD method and construction of phase diagram database

The CALPHAD method is widely applied for the assessment of phase diagrams and phase equilibria in practical alloy systems and is used to calculate various thermodynamic quantities and phase equilibria under the given conditions. Furthermore, the refined methods of thermodynamic assessments based on the CALPHAD enable us to estimate crystal defects, metastable equilibria, and order/disorder transitions in materials and expand the applicable fields of thermodynamics in alloys and materials.

2. Dynamic simulations based on Phase-Field method

We will proceed with the analysis of microstructure formation in practical multicomponent alloys using the phase-field method. The phase-field method is a model proposed for calculating the time variation of material microstructures, capable of analyzing phase transformations (such as changes from solid to liquid phase or changes between different crystal structures), grain boundary movements, and sintering phenomena. The governing equations are derived based on the minimization of total free energy of the system, and by incorporating the free energy evaluated by the CALPHAD method into the energy, it becomes possible to analyze the microstructure of practical alloys.