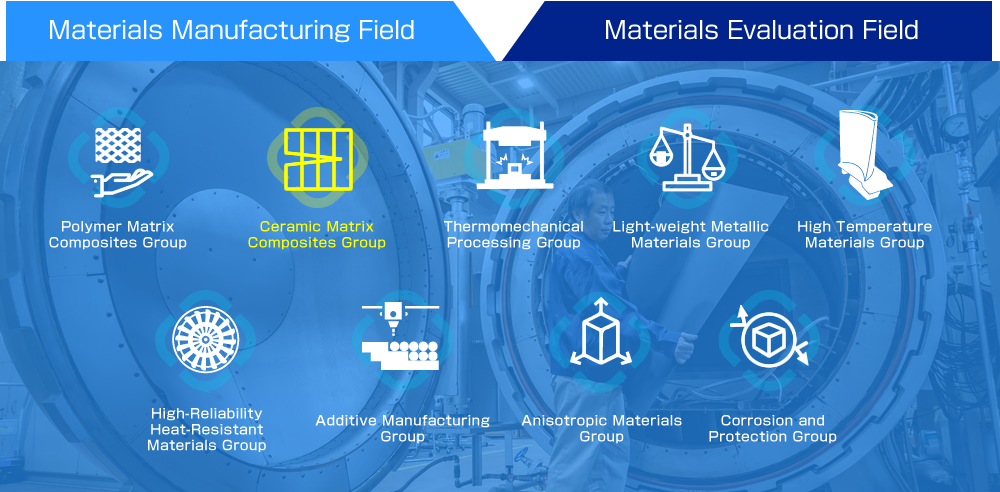

↑Click on the icon to go to other groups

↑Click on the icon to go to other groups

Ceramic Matrix Composites Group

Members

Hideki Kakisawa

Group Leader, Ceramic Matrix Composites Group, Materials Manufacturing Field, Research Center for Structural Materials

Keyword : high-temperature observation, strain measurement, heat-resistant materials, high temperature reaction, high temperature damage![]()

Kazuya Shimoda

Senior Researcher, Ceramic Matrix Composites Group, Materials Manufacturing Field, Research Center for Structural Materials

Keyword : high-temperature materials, silicon carbide (SiC), ceramic matrix composites (CMC), nanoparticles, dispersion/agglomeration, steam oxidation![]()

Gaku Okuma

Senior Researcher, Ceramic Matrix Composites Group, Materials Manufacturing Field, Research Center for Structural Materials

Keyword : sintering, microstructure, defect, X-ray CT

About us

Ceramic matrix composites (CMCs) are damage-tolerant materials avoiding unexpected catastrophic fracture though the use of their composite structure. They have recently been used in the hot sections of civil jet engines due to their low density and excellent mechanical properties at high temperature; their application fields are expected to be expanded to other sections in jet engines and nuclear power plants.

We conduct fundamental researches and developments of CMCs and their environmental barrier coatings (EBCs), including new effective and low cost processing; evaluation techniques of mechanical properties and fracture mechanism; evaluation of degradation in a variety of environments.

Themes

- High- sinterability SiC nano-power processing

- New SiC/SiC processing utilizing greensheets and prepreg sheets

- Evaluation techniques for interface toughness of EBCs

- In-situ microscopic observation and strain distribution measurement over 1400℃