↑Click on the icon to go to other groups

High Temperature Materials Group

About us

With the aim of reducing CO2 emission by improving the thermal efficiency of next generation jet-engines, ultra-high efficient combined cycle power generation, and cogeneration systems, our group is developing various ultra-high temperature heat resistant materials, including high performance Ni-base superalloys. The scope of our activities encompasses interfacial engineering at grain-boundaries and between the solid solution matrix (γ phase) and the coherent precipitates (γ’ phase), mechanical evaluation including creep strength study, coating development and most importantly, the design based approach to the development of low cost high performance alloys. In addition, recycling methods of our developed alloys have also been proposed to make the practical use of our materials feasible.

Specialized Research Field

1. Development of Ni-base Superalloys and new high temperature alloys

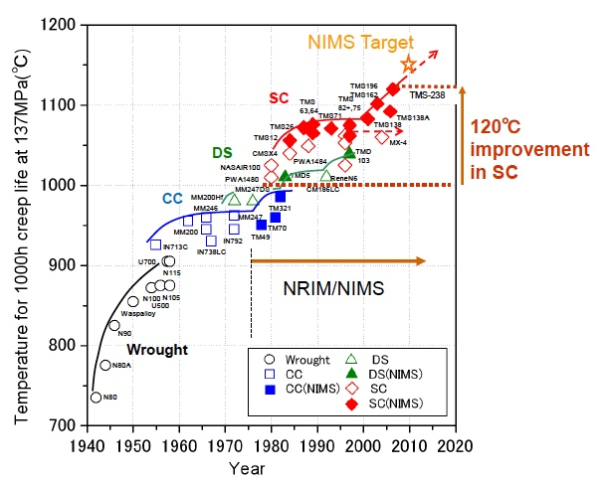

With the purpose of enhancing energy output and efficiency of jet-engines and power generation gas turbines, high temperature creep and oxidation resistant Ni-base superalloys have been developed. Over the decades, temperature capabilities have greatly enhanced (Fig. 1) as casting technologies transformed from wrought, to conventionally cast, directionally solidified and to the current single crystal form. In the development of single crystal Ni-base superalloys, with γ' volume fraction and lattice misfit of γ'/γ being tailored to enhance precipitation strengthening and refinement of interfacial dislocation network spacing, we have successfully developed a new alloy with World highest temperature capability of 1117°C and are working to achieve higher temperature capability. Concurrently, we are also working on achieving lightweight high strength directionally solidified TiAl blades with tailored lamellar structure by interfacial engineering of matrix and precipitated phases, and improved manufacturing processes (Fig. 2).

Fig. 1

Fig. 1

The historical improvement in creep rupture temperature capability of Ni-base superalloys under 1100℃ - 137MPa.

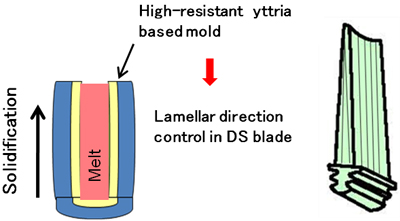

Fig. 2

Development of the process and high performance TiAl alloys

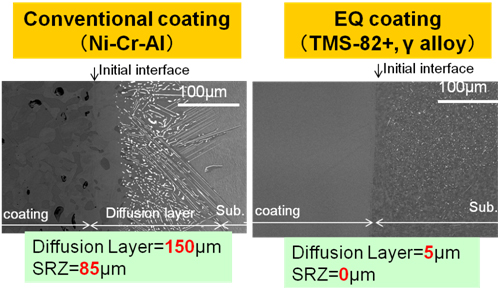

2. Development of the thermodynamic equilibrium coating (EQ coating)

A new coating system which does not form the harm layer in substrate and the coating interface has been developed basing on our new concept of using a material in thermodynamic equilibrium with the substrate (Fig. 3).

Fig. 3

Coating in equilibrium with substrate = EQ Coating

3. Alloy design, Simulation and Microstructure analysis

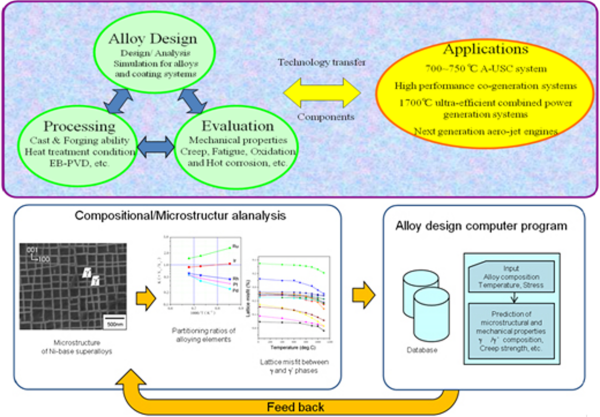

Alloy design, simulation and microstructure analysis are performed using empirical formulae based on database (Fig. 4).

Fig. 4

Alloy Design, Simulation and Microstructure Analysis

Members

Kyoko Kawagishi

Group Leader, High Temperature Materials Group, Materials Manufacturing Field, Research Center for Structural Materials![]()

Keyword : Ni-based superalloy, high temperature creep, thermal fatigue, oxidation resistance![]()

![]()

Rudder Wu

Senior Researcher, High Temperature Materials Group, Materials Manufacturing Field, Research Center for Structural Materials

Ayako Ikeda

Researcher, High Temperature Materials Group, Materials Manufacturing Field, Research Center for Structural Materials

Keyword : Ni-based superalloy, high-throughput measurement, phase diagram, diffusion