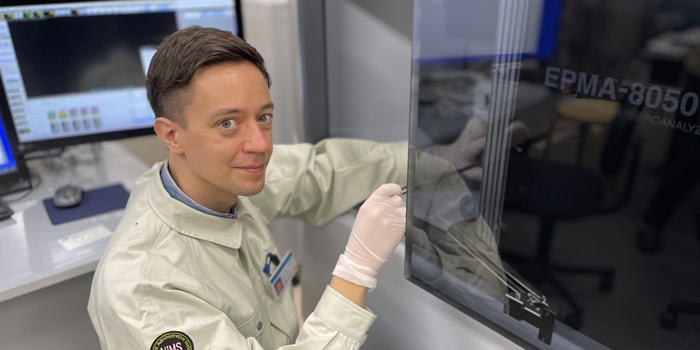

Thomas Hoefler

NIMS Postdoctoral Researcher, High-Reliability Heat-Resistant Materials Group, Materials Manufacturing Field, Research Center for Structural Materials

Hobbies

Cooking and baking/breadmaking, cycling, DSLR photography, computers

Special skills

Automatic measurements and data analysis

Q&A

Q:How did you come to know about NIMS?

A:During my Postdoc at Kyushu University, I frequently used the Computational Phase Diagram Database (CPDDB) maintained at NIMS, and also attended several talks by NIMS researchers at conferences in Japan. I also encountered NIMS during my daily life in Japan. For example, NIMS featured on the TV program "Knight Scoop" by the Asahi Broadcasting Corporation, kindly answering a viewer asking "Please tell me what this mysterious object is".

Q:How did you get involved in materials research?

A:When I was a university student, I was fascinated when saw metallographic sections of cast steels in a light microscope for the first time. As I found the versatility and ubiquitousness of iron-based materials interesting, I mainly performed research concerning oxidation phenomena and microstructure analysis, which I find also has an artistic appeal. After that I began to work on superalloys, where I was also able to apply my programming experience - which I did as a hobby - to numerical simulations for prediciton of material properties.

Q:What is the attraction of NIMS?

A:I visited NIMS just before starting as a Postdoc researcher, and was impressed by the amount and quality of research equipment present (especially by the electron microscopes). Before joining, I was unsure how the interpersonal relationships and life in Tsukuba would be (which is difficult to grasp from just one short visit), but I soon found an environment where I could always ask for advice when in need and Tsukuba offers many recreational opportunities for cycling, walking and public parks.

Q:What is your research topic, and what attracts you to it?

A:The aim of my research here is to develop an automatic, high-throughput analysis method to acquire large amounts of data in a short time, hoping to contribute to the optimization of superalloys, which are commonly found in turbine blades and discs. The topic has a good balance between experimental and computational work, and since it is a highly interdisciplinary and multifaceted topic, there are always opportunities for a change of pace or approach. I often come up with a solution to a problem when working on a different problem. Further, the method is not only applicable to superalloys, but to all kinds of materials, for example to gather phase diagrams or heat treatment data.