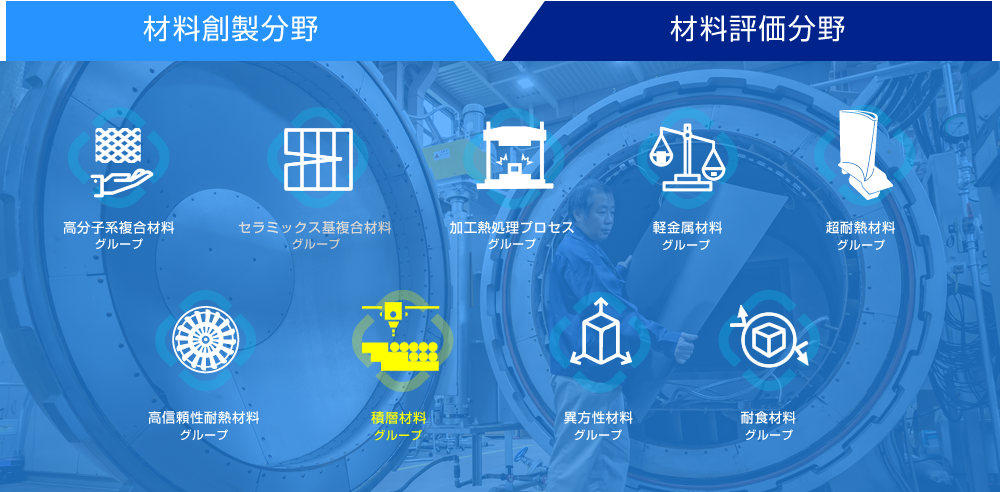

↑他グループへはアイコンをクリック

↑他グループへはアイコンをクリック

積層材料グループ

Additive Manufacturing Group

積層材料グループでは、次世代のプロセス技術として注目される三次元積層造形 (3Dプリンタ) や、部材の保護技術として重要な溶射コーティングについて、研究開発を行なっています。ジェットエンジンやガスタービンなど高温エネルギー機器で利用される耐熱材料 (Ni基合金やTi合金、酸化物セラミックス等) を対象としています。

共同研究募集中 !

3D造形プロセスや溶射に関する共同研究を募集しています。

【お問い合わせ先】

渡邊 誠(わたなべ まこと)

WATANABE.Makoto=nims.go.jp([ = ] を [ @ ] にしてください)

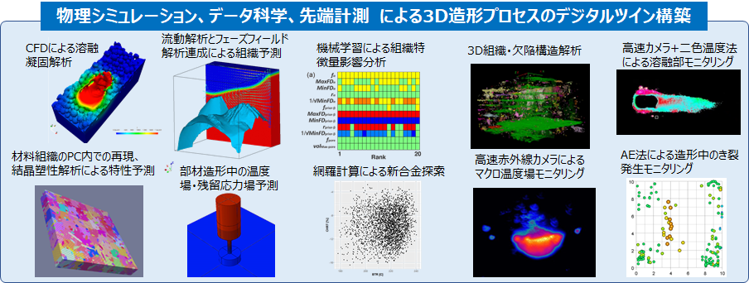

研究概要

原料粉末から複雑な三次元構造を直接作成可能な3D積層造形プロセスについて、プロセス条件と材料組織、特性の相関について、実験および計算による予測の両面から研究を進めています。Ni基合金 (ハステロイX、Inconel 738LC等) や、Ti合金(Ti-6Al-4V、Ti-Nb)、耐熱鋼 (改良9Cr-1Mo鋼) 、ステンレス等、様々な構造材料を対象として、3D造形ならではの組織制御技術の確立や力学特性の最適化に取り組んでいます。さらに、これらの知見に基づいて、3D造形に適した新しい材料開発にも挑戦しています。この他にも、過酷な環境から部材を保護するための溶射コーティングや、信頼性確保のための非破壊評価技術についても研究しています。

3Dプリンター(金属AM装置)

定年制職員

渡邊 誠 WATANABE Makoto

構造材料研究センター 副センター長

グループリーダー

何 東風 HE Dongfeng

主幹研究員

磁気センサ,非破壊検査,サーモグラフィー,渦電流,電磁,鉄筋腐食,積層材料欠陥

マーサー クリストファー MERCER Christopher

主幹研究員

Low Thermal Expansion, Auxetics, Lattices, Additive Manufacturing, Geometry Optimization

Crystal Plasticity, Finite Element Method, Continuum Mechanics, Fatigue and Fracture, Digital Image Correlation

任期制職員

研修生(連携大学院生等)

- 仲山 大晴 NAKAYAMA Taisei

NIMSジュニア研究員 - シュレイ メダ SHREY Medha

NIMSインターンシップ生 - マンガム スバカル MANGAM Subhakar

国際連携大学院生 - ヘ リ 何 櫟

研修生 - ガリエグ ルイ マクシミリアン マリ GALIEGUE Louis Maximilien Marie

研修生

論文リスト

2025年

![]() Meng L., Kitashima T., Lin P., Wang Z., Jiang Z., Huang Q., Zhao J.

Meng L., Kitashima T., Lin P., Wang Z., Jiang Z., Huang Q., Zhao J.

Achieving polymer-like ultrahigh elasticity in Ti−6Al−4V alloy via a new cryo-deformation induced α′-to-α″ martensite phase transformation

Acta Materialia.293(2025)121109

![]() Daram P., Kusano M., Watanabe M.

Daram P., Kusano M., Watanabe M.

Investigation of the Process Optimization for L-PBF Hastelloy X Alloy on Microstructure and Mechanical Properties

Materials.18[8](2025)1890

![]() Bhandari L., Gaur V., Briffod F., Shiraiwa T., Enoki M.

Bhandari L., Gaur V., Briffod F., Shiraiwa T., Enoki M.

High-temperature fatigue and creep damage mechanism in additively manufactured Ti-6Al-4V alloy

Engineering Failure Analysis.174(2025)109534

Katagiri J., Nomoto S., Kusano M., Watanabe M.

Influence of high Reynolds number flow inside molten pool on keyhole instability-induced pore formation process in laser powder bed fusion

Materials Today Communications.44(2025)111756

Nomoto S., Kusano M., Kitashima T., Watanabe M.

Numerical simulation method for the laser powder bed fusion process by lattice Boltzmann and multi-phase field methods

Computational Materials Science.250(2025)113688

Meng L., Kitashima T., Lin P., Zheng L., Jiang Z., Zhao J.

In situ EBSD investigation of microtexture evolution and slip activation of α macrozones during tensile deformation in Ti-6Al-4V alloy

Materials Science and Engineering: A.924(2025)147739

Honda H., Watanabe M.

Measurement of Laser Absorptivity of Inconel Powders with Additive Manufacturing Machine

Materials Transactions.66[1](2025)107-112

Briffod F., Yasuda K., Zhu J., Shiraiwa T., Jhon M., Gunawan F., Sahay R., Raghavan N., Budiman A.S., Enoki M.

Fatigue and fracture of accumulative roll-bonded Cu/Nb materials: Effects of layer thickness and loading direction

International Journal of Fatigue.193(2025)108772

2024年

Mercer C., Hasegawa A., Hosoda N.

Surface-activated bonding between a 3D-printed Ti-6Al-4V structure and bulk aluminum

Journal of Materials Science: Materials in Engineering.19[1](2024)47

Kuroda T., Masuyama H., Toda Y., Matsunaga T., Ito T., Watanabe M., Ozasa R., Ishimoto T., Nakano T., Shimojo M., Yamabe–Mitarai Y.

Microstructure Evolution and High–Temperature Mechanical Properties of Ti–6Al–4Nb–4Zr Fabricated by Selective Laser MeltingNippon Kinzoku Gakkaishi/Journal of the Japan Institute of Metals.88[12](2024)348-356

Bulgarevich D.S., Watanabe M.

Stress–strain curve predictions by crystal plasticity simulations and machine learning

Scientific Reports.14[1](2024)29492

Hagiwara M., Kitashima T.

High Cycle Fatigue and Very High Cycle Fatigue of Orthorhombic (O + α2)–Type Ti–27.5Nb–13Al Alloy with and without B and Fatigue Striation Analysis in Comparison with (α + β)–Type Titanium Alloys

Nippon Kinzoku Gakkaishi/Journal of the Japan Institute of Metals.88[12](2024)357-366

Katagiri J., Nomoto S., Kusano M., Watanabe M.

Effect of mushy zone constant in Voller-Prakash model on keyholing behaviour in laser powder bed fusion simulation

Results in Engineering.24(2024)103567

Verona I.C.M., Bardolaza H.R., Juguilon V.P.P., Bulgarevich D.S., Watanabe M., Tani M., Estacio E.S.

Investigation of Spin-Current Lifetime in Fe/Pt Spintronic Terahertz Emitter using Double Optical Pump Technique

International Conference on Infrared, Millimeter, and Terahertz Waves, IRMMW-THz.(2024)

Kusano M., Watanabe M.

Controlling heat accumulation through changing time per layer in laser powder bed fusion of nickel-based superalloy

Journal of Manufacturing Processes.131(2024)187-198

Hatakeyama T., Sawada K., Kusano M., Watanabe M.

Significant creep-strength improvement in modified 9Cr-1Mo steel via microstructural control through laser powder bed fusion

Additive Manufacturing.93(2024)104445

Morimoto T., Katoh H., Ishida Y., Hara E., Kusano M., Naito K., Watanabe M., Takagi K., Arai K., Hasegawa K.

Modified double cantilever beam test method for mode-I energy release rate of elastic adhesive layers

Engineering Fracture Mechanics.307(2024)110320

Daram P., Morisada Y., Ogura T., Kusano M., Yu J., Fukuda M., Fujii H., Kuroda S., Watanabe M.

Development of Tungsten Repair Technology by Atmospheric Plasma Spraying of Tungsten and Friction Stir Processing

Journal of Thermal Spray Technology.(2024)

Daram P., Singh A., Hiroto T., Kitashima T., Watanabe M.

Compositionally graded titanium to aluminum processed by laser powder bed fusion process: Microstructure evolution and mechanical properties

Materials Science and Engineering: A.903(2024)146638

Kitashima T., Hiroto T., Jodi D.E., Watanabe M.

Fabricating a single-crystal-like β grain structure of a near-β Ti alloy with unique variant selection by laser powder bed fusion

Materials and Design.243(2024)113039

Katagiri J., Nomoto S., Kusano M., Watanabe M.

Particle Size Effect on Powder Packing Properties and Molten Pool Dimensions in Laser Powder Bed Fusion Simulation

Journal of Manufacturing and Materials Processing.8[2](2024)71

Kitashima T., Hiroto T., Watanabe M.

Numerical analysis of Al2O3 and TiO2 growth and oxygen dissolution in a metal substrate during the isothermal oxidation of an α-Ti alloy at 973 K

Journal of Materials Research and Technology.30(2024)4137-4146

Okugawa M., Saito K., Yoshima H., Sawaizumi K., Nomoto S., Watanabe M., Nakano T., Koizumi Y.

Solute segregation in a rapidly solidified Hastelloy-X Ni-based superalloy during laser powder bed fusion investigated by phase-field and computational thermal-fluid dynamics simulations

Additive Manufacturing.84(2024)104079

Mercer C., Hosoda N.

Analysis of Structure and Function of Ladybird Leg and Subsequent Design and Fabrication of a Simplified Leg Structure for Robotic Applications

Biomimetics.9[3](2024)184

Honda H., Watanabe M.

Quantifying Laser Absorptivity of Ti–6Al–4V Powder through Additive Manufacturing Systems

Materials Transactions.65[2](2024)194-198

Kusano M., Takata Y., Yumoto A., Watanabe M.

Effects of time per layer and part geometry on thermal history and microcracking in the fabrication of nickel superalloy samples by laser powder bed fusion

Additive Manufacturing.80(2024)103987

Kusano M., Watanabe M.

Heat Source Model Development for Thermal Analysis of Laser Powder Bed Fusion Using Bayesian Optimization and Machine Learning

Integrating Materials and Manufacturing Innovation.(2024)

2023年

Zhu J., Briffod F., Shiraiwa T., Enoki M., Emura S.

Kink band formation mechanism in α/β Ti-9Cr two-phase alloy

Journal of Alloys and Compounds.939(2023)168736

Wang Q., Ma N., Huang W., Shi J., Luo X.-T., Tomitaka S., Morooka S., Watanabe M.

Key role of temperature on delamination in solid-state additive manufacturing via supersonic impact

Materials Research Letters.11[9](2023)742-748

Wang Q., Ma N., Chen J., Tomitaka S., Watanabe M.

Microstructure characteristics of warm spray additively manufactured Inconel 718 superalloys and correlation with mechanical performance

Materials Letters.341(2023)134230

Talara M., Bulgarevich D.S., Kobayashi K., Kitahara H., Furuya T., Escano M.C., Watanabe M., Tani M.

Impact of Antenna Metal's Thicknesses and Structures on Terahertz (THz) Wave Generation Performance of Spintronic Emitters

International Conference on Infrared, Millimeter, and Terahertz Waves, IRMMW-THz.(2023)

Osada T., Koyama T., Bulgarevich D.S., Minamoto S., Osawa M., Watanabe M., Kawagishi K., Demura M.

Virtual heat treatment for γ-γ′ two-phase Ni-Al alloy on the materials Integration system, MInt

Materials and Design.226(2023)111631

Meng L., Kitashima T., Zhao Z., Wei Q., Lin P.

Effect of parent β-texture on α-texture evolution during dynamic precipitation in a continuous forging process of Ti-6Al-4V alloy

Journal of Alloys and Compounds.947(2023)169425

Kuroda T., Masuyama H., Toda Y., Matsunaga T., Ito T., Watanabe M., Ozasa R., Ishimoto T., Nakano T., Shimojo M., Yamabe-Mitarai Y.

Microstructure Evolution and High-Temperature Mechanical Properties of Ti6Al4Nb4Zr Fabricated by Selective Laser Melting

Materials Transactions.64[1](2023)95-103

Katagiri J., Kusano M., Minamoto S., Kitano H., Daimaru K., Tsujii M., Watanabe M.

Melt Pool Shape Evaluation by Single-Track Experiments and Finite-Element Thermal Analysis: Balling and Lack of Fusion Criteria for Generating Process Window of Inconel738LC

Materials.16[4](2023)1729

Jodi D.E., Kitashima T., Singh A., Watanabe M.

High-temperature microstructural stability of pure Ni fabricated by laser powder bed fusion using Gaussian and flat-top beam profiles

Materials Characterization.200(2023)112897

Hatakeyama T., Sawada K., Suzuki M., Watanabe M.

Microstructure development of modified 9Cr-1Mo steel during laser powder bed fusion and heat treatment

Additive Manufacturing.61(2023)103350

Hagiwara M., Kitashima T.

High Cycle Fatigue and Very High Cycle Fatigue of Orthorhombic (O + α 2 )-Type Ti–27.5Nb–13Al Alloy with and without B and Fatigue Striation Analysis in Comparison with (α + β)-Type Titanium Alloys

Materials Transactions.64[1](2023)121-130

Daram P., Hiroto T., Watanabe M.

Microstructure and phase evolution of functionally graded multi-materials of Ni–Ti alloy fabricated by laser powder bed fusion process

Journal of Materials Research and Technology.23(2023)5559-5572

Bulgarevich D.S., Nomoto S., Watanabe M., Demura M.

Crystal plasticity simulations with representative volume element of as-build laser powder bed fusion materials

Scientific Reports.13[1](2023)20372

Zhu J., Briffod F., Shiraiwa T., Enoki M., Emura S.

High-Resolution Digital Image Correlation Analysis of Layered α/β Two-Phase Ti–12Mo Alloy under Compressive Condition

Materials Transactions.64[12](2023)2677-2686

Kitahara H., Ishii K., Talara M., Furuya T., Escano M.C., Tani M., Bulgarevich D.S., He D., Watanabe M.

Improvement in the Detection Efficiency of Terahertz (THz) Time-domain Spectroscopy (TDS) by applying an Alternating Magnetic Field Bias in Spintronic Emitter

International Conference on Infrared, Millimeter, and Terahertz Waves, IRMMW-THz.(2023)