↑他グループへはアイコンをクリック

↑他グループへはアイコンをクリック

Corrosion Research Group

About us

Corrosion of metal materials is one of the factors that cause structural deterioration and damage, resulting in economic loss. The Corrosion Research Group investigates the corrosion deterioration behavior at the surface and interface of metal materials in various environments, in order to solve many corrosion problems. Furthermore, through the elucidation of these mechanisms, we aim to contribute to improving the reliability and durability of metal materials in various usage environments.

Members

Group Leader, Corrosion Research Group, Materials Evaluation Field, Research Center for Structural Materials

Keyword : stainless steel, corrosion resistance, surface treatment, electrochemistry, corrosion protection, laser process![]()

Hideki Katayama

Chief Researcher, Corrosion Research Group, Materials Evaluation Field, Research Center for Structural Materials

Keyword : infrastructure, steel, corrosion, outdoor corrosion testing, steel rust, machine learning, hyperspectral![]()

Yoshiharu Murasae

Senior Researcher, Corrosion Research Group, Materials Evaluation Field, Research Center for Structural Materials

Keyword : structural materials, corrosion resistance evaluation, crystal structure analysis, microscopic analysis, electrochemical testing

Mariko Kadowaki

Senior Researcher, Corrosion Research Group, Materials Evaluation Field, Research Center for Structural Materials

Keyword : iron and steel, lightweight metals, corrosion, electro-chemical measurement, finite element method![]()

Specialized Research Field

1. Advancement of atmospheric corrosion monitoring technology for steel materials and establishment of non-destructive corrosion risk prediction technology

The cost of repairing and updating aging social infrastructure is expected to become enormous in the future. In order to use these safely for a long time in the future, it is necessary to switch from the conventional corrective maintenance type to the preventive maintenance type. It is important to accurately grasp the current situation and predict risks in preventive maintenance. In this theme, we aim to improve the atmospheric corrosion rate monitoring technology for understanding the corrosion status of steel materials and to establish corrosion risk prediction technology using a simple non-destructive evaluation method.

2. Evaluation of Corrosion Behavior by using combined SKPFM-EBSD-EDS analysis

Evaluation of corrosion behavior dependent on the microstructure of structural materials is conducted by using analyses of scanning Kelvin probe force microscopy (SKPFM) as well as electron backscatter diffraction (EBSD) and energy dispersive X-ray spectroscopy (EDS) in scanning microscopy. The locations of corrosion initiation can be mapped by detecting changes in surface potential in SKPFM analysis, the corrosion resistance based on crystal structure is evaluated by EBSD analysis, and the formation of inclusions and elemental segregation involved with corrosion reactions are detected by EDS analysis. The purpose of this research is to obtain a structural material design guideline with excellent corrosion resistance by combining these three different analyses.

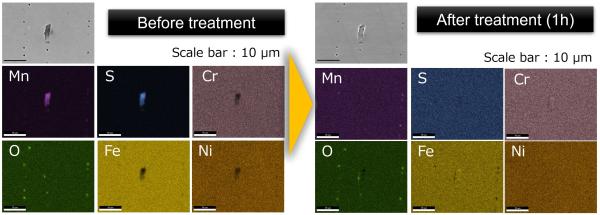

3. Development of novel surface treatment techniques realizing extremely-enhanced corrosion resistance for metallic materials

We are developing the surface treatment techniques for improvement of stainless steel surfaces to minimize the risk of unexpected corrosion failure and accidents, enabling reliable utilization of the steels. These treatments are performed under newly-developed electric current and potential conditions in a specific treatment solution. Only the exposed defects (impurity particles) exposed on the steel surface, which are the initiation sites of localized corrosion, are successfully dissolved and removed. It has been confirmed that stainless steel reinforced by this treatment shows totally corrosion resistance even in severe corrosive environments such as artificial seawater and hydrochloric acid. This technique is expected to be used for structural materials, medical implants, and fuel cells.

The developed surface treatment that selectively removes only the defects

(manganese and sulfides inclusions) inducing localized corrosion from stainless steel surface.

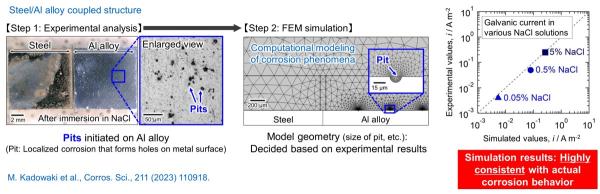

4. Clarifying the corrosion mechanisms of metals by combining experimental and computational simulation techniques

We are using both experimental techniques and computational simulations to clarify the corrosion mechanisms of metals and to improve their corrosion resistance. For example, we are conducting numerical simulations based on finite element method (FEM) to analyze the corrosion behavior of dissimilar metal couples, and first-principles calculations to elucidate the effect of alloying elements on the corrosion behavior of steels.

Corrosion analysis of steel/Al alloy couple using FEM simulation.