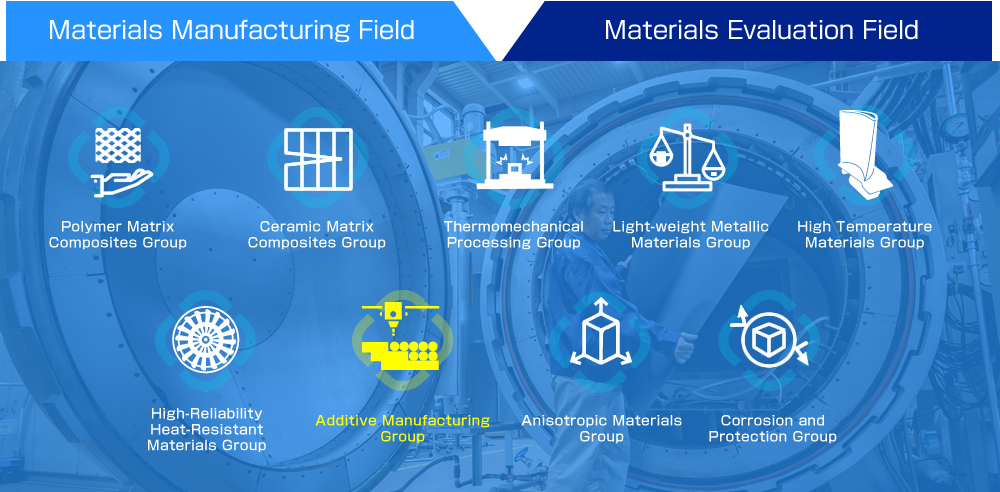

↑Click on the icon to go to other groups

↑Click on the icon to go to other groups

Additive Manufacturing Group

Members

Makoto Watanabe

Deputy Director, Research Center for Structural Materials

Keyword : additive manufacturing, thermal spray coatings, metallic materials, heat-resistant materials, materials integration, DX, numerical simulation![]()

Dongfeng He

Principal Researcher, Additive Manufacturing Group, Materials Manufacturing Field, Research Center for Structural Materials

Keyword : magnetic sensors, nondestructive testing, thermography, eddy current, electromagnetic, rebar corrosion, laminate material defects

Tomonori Kitashima

Principal Researcher, Additive Manufacturing Group, Materials Manufacturing Field, Research Center for Structural Materials![]()

Keyword : titanium alloy, nickel-based superalloy, additive manufacturing, high-temperature deformation, microstructure control, precipitation, phase transformation, texture, single crystal![]()

Christopher Mercer

Principal Researcher, Additive Manufacturing Group, Materials Manufacturing Field, Research Center for Structural Materials

Keyword : low thermal expansion, auxetics, lattices, additive manufacturing, geometry optimization

Masahiro Kusano

Senior Researcher, Additive Manufacturing Group, Materials Manufacturing Field, Research Center for Structural Materials

Keyword : metal additive manufacturing, finite element thermal analysis, process monitoring, microstructure control![]()

Fabien Briffod ![]()

Researcher, Additive Manufacturing Group, Materials Manufacturing Field, Research Center for Structural Materials

Crystal Plasticity, Finite Element Method, Continuum Mechanics, Fatigue and Fracture, Digital Image Correlation

About us

Additive Manufacturing Group studies on additive manufacturing (3D printer), which has been attracting a lot of interest as a next-generation process technology, and thermal spray processing, which is important for a protective coating of a structural component in harsh environments. The group focuses on heat-resistant materials (Ni-based alloys, Ti alloys, oxide ceramics, etc.) used in jet engines, gas turbines, and other high-temperature energy equipment.

Group research overview

In this group, mainly four research topics have been investigated, (i) 3D additive manufacturing process that directly creates complex three-dimensional structures from raw material powder, (ii) Coating technology to protect structural components from harsh environments, and (iii) Nondestructive evaluation techniques for ensuring reliability of materials.

Research theme

Selective laser Melting

Sukeharu Nomoto, Masahito Segawa, Makoto Watanabe. Non- and Quasi-Equilibrium Multi-Phase Field Methods Coupled with CALPHAD Database for Rapid-Solidification Microstructural Evolution in Laser Powder Bed Additive Manufacturing Condition. Metals. (2021) 626-1-626-21 10.3390/met11040626

KITANO, Houichi, TSUJII, Masakazu, KUSANO, Masahiro, Atsushi Yumoto, WATANABE, Makoto. Effect of plastic strain on the solidification cracking of Hastelloy-X in the selective laser melting process. Additive Manufacturing. (2021) 101742-1-101742-9

Kaita Ito, Masahiro Kusano, Masahiko Demura, Makoto Watanabe. Detection and location of microdefects during selective laser melting by wireless acoustic emission measurement. Additive Manufacturing. 40 (2021) 101915 10.1016/j.addma.2021.101915

Image Segmentation and Analysis for Microstructure and Property Evaluations on Ti–6Al–4V Fabricated by Selective Laser Melting

Spray Coating

Effects of Gun Scanning Pattern on the Structure, Mechanical Properties and Corrosion Resistance of Plasma-Sprayed YSZ Coatings

Effects of amorphous phase on hot corrosion behavior of plasma-sprayed LaMgAl11O19 coating

Non-destructive Evaluation

Evaluation of 3D-Printed titanium alloy using eddy current testing with high-sensitivity magnetic sensor

Terahertz Magneto-Optic Sensor/Imager

Mid-infrared pulsed laser ultrasonic testing for carbon fiber reinforced plastics

Forging

Effect of α precipitation on β texture evolution during β-processed forging in a near-β titanium alloy