↑Click on the icon to go to other groups

↑Click on the icon to go to other groups

Corrosion and Protection Group

About us

The realization of a low-carbon society requires the reduction of greenhouse gas emissions by reducing the weight of transportation equipment like automobiles. Al and Mg alloys, which are expected to be lightweight materials, have the problem of low corrosion resistance. On the other hand, by taking advantage of the low corrosion resistance, the application of Mg alloys in biodegradable medical devices are being examined. We are developing corrosion control coatings for metallic materials such as Mg alloys, which are suitable for various applications.

Extending the service life of structures will help shift from a "scrap-and-build" flow-oriented society to a stock-oriented society and achievement to a recycling-oriented and low-carbon society. Deterioration of concrete structures is caused by a corrosion of steel rebars, so that development of corrosion-resistant rebars and surface modification are being carried out. We are elucidating the effects of various corrosion factors on the corrosion mechanism of steel rebars using an original accelerated corrosion test method developed for rebars in concrete.

Through the surface modification and corrosion evaluation of metallic materials, we aim to contribute to the practical application and the reliability improvement of various metallic materials.

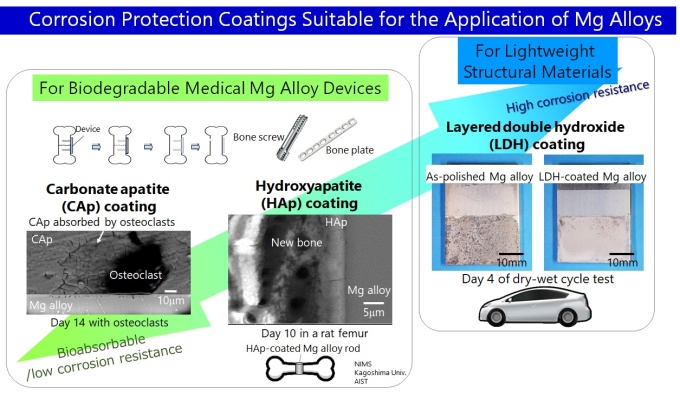

Corrosion Protection Coatings Suitable for the Application of Mg Alloys

Mg alloys are attracting attention as lightweight materials and as biodegradable materials. However, too low corrosion resistance is an issue for practical use in both applications.

Layered double hydroxide (LDH), a corrosion product formed on Mg alloys in coastal areas, is used for the corrosion protection coating of Mg alloys for lightweight materials. For Mg alloys for medical applications, we are developing hydroxyapatite (HAp) coatings that are stable in vivo and carbonate apatite (CAp) coatings that are absorbed by osteoclasts.

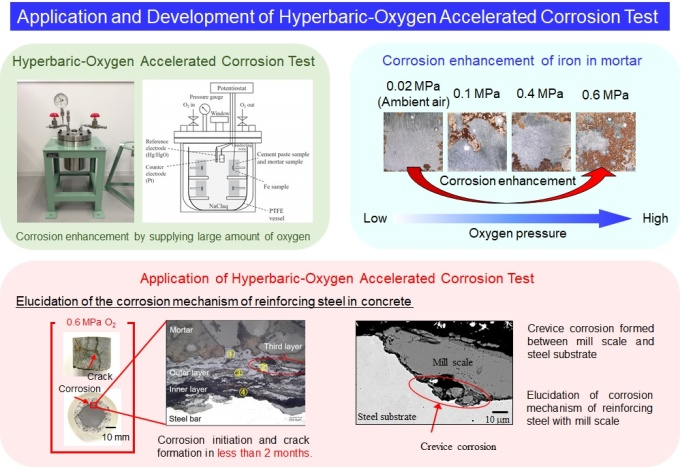

Application and Development of Hyperbaric-Oxygen Accelerated Corrosion Test

In the corrosion reaction of metallic materials, oxidation reaction (= dissolution of metal) and reduction reaction (= oxygen reduction) always proceed at the same time at an equal rate. We have developed a "hyperbaric-oxygen corrosion accelerated test" that accelerates the oxygen reduction reaction on the surface of metallic materials by increasing the oxygen concentration (partial pressure) in the test environment, thereby accelerating the corrosion reaction. We are working on the elucidation of corrosion of various metallic materials and the development of new anti-corrosion technologies using our original test method.

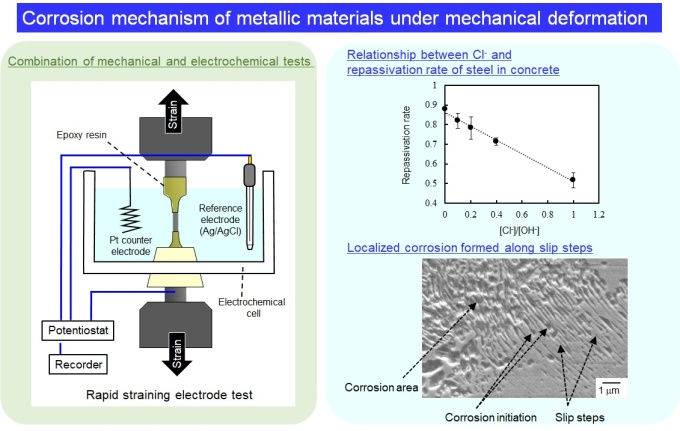

Elucidation of the Corrosion Mechanism of Metallic Materials under Mechanical Deformation

Bridges and highways are now subjected to greater cyclic loads than when they were designed due to the increase in the size of vehicles and the volume of traffic. In addition, typhoons are becoming larger and the forces applied to buildings are also increasing. Corrosion of metallic materials is accelerated by the synergistic effect of chemical corrosion factors and mechanical deformation due to cyclic loading (fatigue loading). We are working on the elucidation of the corrosion mechanism of metallic materials such as steel in concrete, stainless steel, and Mg alloys used under mechanical deformation.

Members

Sachiko Hiromoto

Group Leader, Corrosion and Protection Group, Materials Manufacturing Field, Research Center for Structural Materials![]()

Keyword : magnesium alloys, aluminum alloys, apatite, layered double hydroxides, corrosion resistant coatings, self-healing coatings, hydrogen embrittlement![]()

Kotaro Doi

Senior Researcher, Corrosion and Protection Group, Materials Manufacturing Field, Research Center for Structural Materials

Keyword : corrosion and protection, oxygen reduction, corrosion in concrete, surface treatment, hydrogen entry, hydrogen embrittlement![]()

![]()