2024年8月9日、NIMSにて、Dr. Zhaoyang Cheng と Dr. Shiqi Zhangによるご講演が第159回構材ゼミとして開催されました。

日時:2024年8月9日(金曜日)15:00~16:30

会場:先進構造材料研究棟 5階カンファレンスルーム

講師:Dr. Zhaoyang Cheng, Dr. Shiqi Zhang(Wuhan University of Science and Technology)

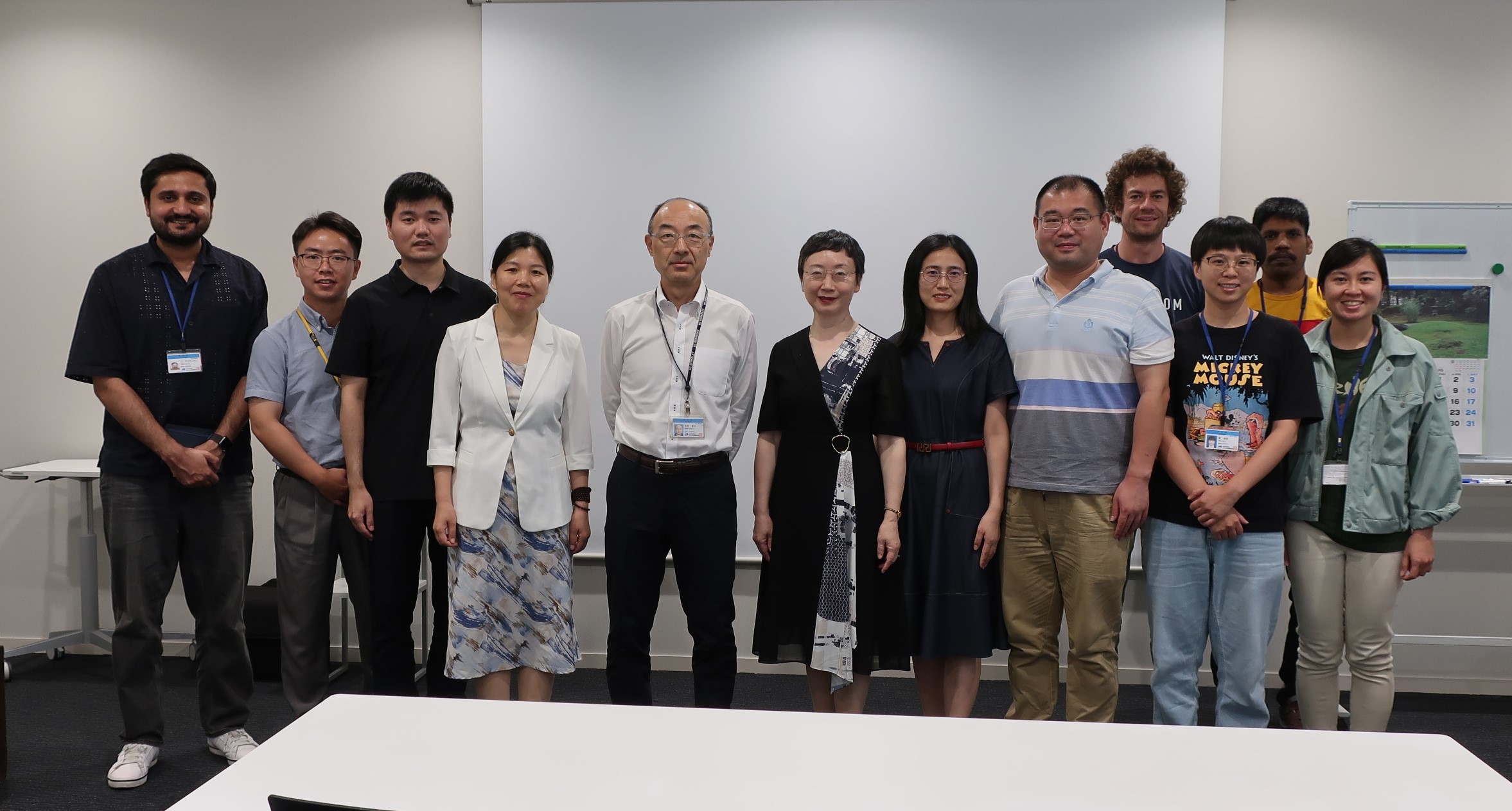

講演後の集合写真

Dr. Zhaoyang Cheng(前列 右から4人目)

Dr. Shiqi Zhang(左から3人目)

Lecture 1

演題:Optimized Rolling Processes to Balance Magnetic and Mechanical Properties of High-strength Non-oriented Electrical Steels

講師:Dr. Zhaoyang Cheng

The State Key Laboratory of Refractories and Metallurgy, Wuhan University of Science and Technology, Wuhan

Lecture 2

演題:Hydrogen embrittlement of additively manufactured maraging steels: mechanistic understanding and H-tolerant structure design

講師:Dr. Shiqi Zhang

The State Key Laboratory of Refractories and Metallurgy, Wuhan University of Science and Technology, Wuhan, Hubei 430081, China

Lecture 1

Abstract:A bottleneck in the development of high-strength non-oriented silicon steels for drive motors of new energy vehicles is the balance of strength and magnetic properties. This paper successfully tackled this problem through the optimization of thickness reduction for hot and cold rolling and the formation of coherent precipitates using a Cu-alloyed non-oriented silicon steel. More specifically, a thickness reduction of 96% in the course of hot rolling promoted the homogenization of microstructure during the following normalization treatment. Subsequently, a deformation degree of 80% during cold rolling ensured the inheritance of the uniform microstructure and inhibited the abnormal growth of recrystallized grains during annealing, thereby suppressing the iron loss to a value as low as 15.6 W/kg. At the meantime, this combined process promoted the inheritance of λ-fibers and the formation of {114}<481> texture in the annealed sheet, improving the magnetic induction intensity B50 to 1.606 T. In addition, under the joint effect of a variety of strengthening mechanisms, the yield strength of this annealed sheet reached 668 MPa. A pronounced increase in strength, about 207 MPa, was derived from precipitation hardening by the great difference in the modulus between coherent Cu-rich clusters and the α-Fe matrix.

Speaker Bio: Dr. Cheng is an Associate Professor and doctoral supervisor who received her Ph.D. from Wuhan University of Science and Technology. She completed her postdoctoral fellowship at the Technical University of Freiberg, Germany. Her primary research interests encompass high-performance metal materials, high-quality electrical steels, and computational materials science. Dr. Cheng has led and participated in over 10 national and provincial-level scientific research projects, including those funded by the National Natural Science Foundation of China, the Key R&D Program of Hubei Province, the Natural Science Foundation of Hubei Province, and the China Postdoctoral Science Foundation. She has published more than 50 papers and holds over 10 patents.

Lecture 2

Abstract: The utilization of additive manufacturing technologies, such as laser-powder bed fusion (LPBF), in fabricating maraging steel has gained increasing attention in recent years. However, the strength–hydrogen embrittlement (HE) resistance trade-off is a critical issue that restricts the application of LPBF maraging steel in hydrogen-containing environments. In this work, advanced hydrogen trap characterization and high-resolution electron microscopy techniques have been utilized to probe the hydrogen trapping sites and reveal the mechanisms of hydrogen-assisted cracking in LPBF maraging steel. Furthermore, based on the computational simulation and novel heat treatment processes, a novel strategy for design of a multi-scale and multi-dimensional hydrogen trap network in LPBF maraging steel, which enable simultaneous enhancement of the strength and HE resistance is proposed. This work provides new insight into the design of HE resistance steels fabricated by additive manufacturing and motivates the industrial application of LPBF maraging steels.

Speaker Bio: Dr. Shiqi Zhang received his PhD degree from Tsinghua University and is currently working as an Associated professor at Wuhan University of Science and Technology. Prof. Zhang’s current research focuses on the hydrogen embrittlement and stress corrosion of metals, and advanced electron microscopy techniques. He has been awarded as Young Elite Scientists Sponsorship Program by CAST, Chutian Scholars of Hubei Province, and Wuhan Talents. He has obtained 10 fundings from government and enterprises, including National Natural Science Foundation of China and CNPC Innovation Funding. He has published more than 40 papers and is the author of 7 patents. He is also the young editorial board member of Journal of Iron and Steel Research, Journal of Engineering Science, and reviewer of Corrosion Science and other journals.